At the TaiyangNews PV Module Reliability Conference, GCL presented its comprehensive strategy for enhancing module durability, controlling degradation, and delivering predictable long-term energy yield.

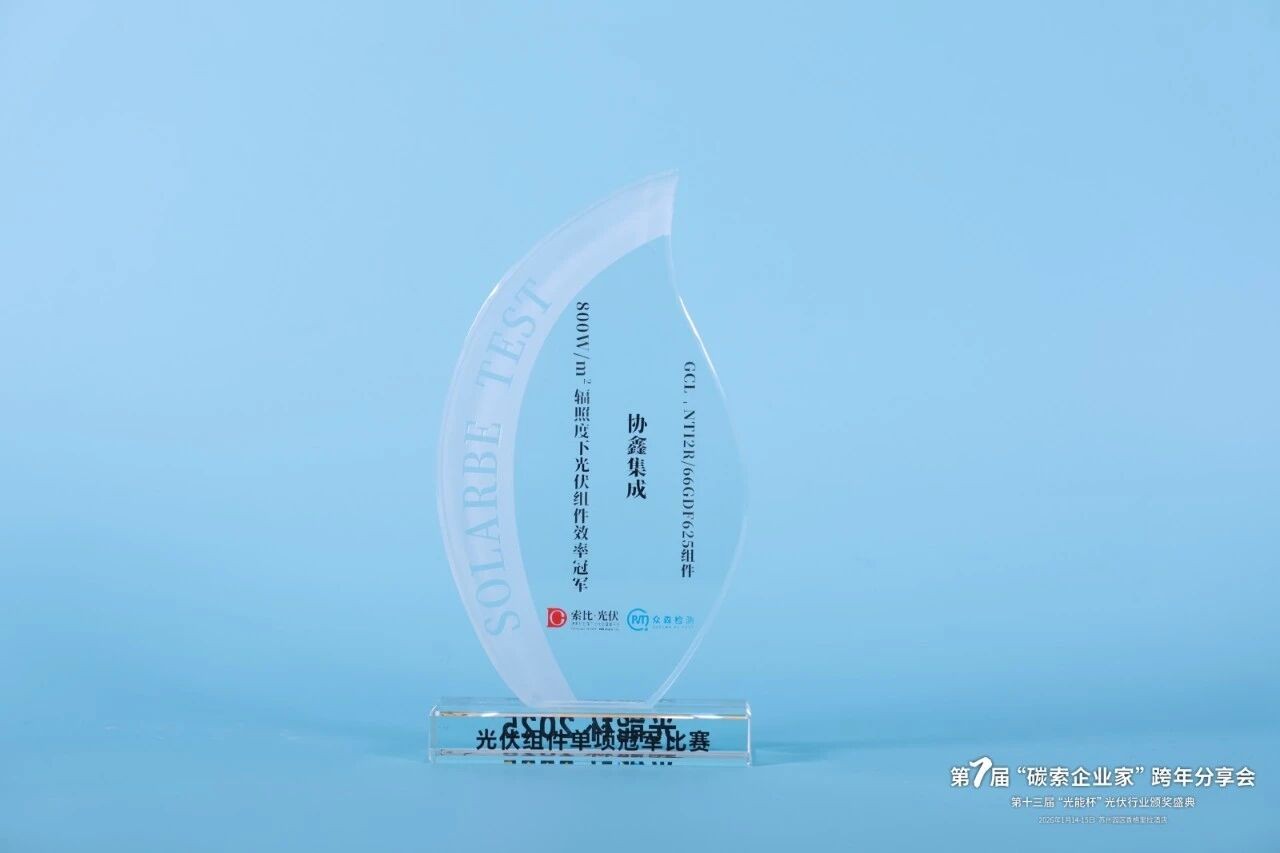

Rojen Malachi, Technical Support Director for Europe at GCL, outlined how the company’s fully vertically integrated manufacturing model—spanning from metallurgical silicon to finished modules—enables systematic quality control and long-term performance stability.

Reliability as the Foundation of Solar Asset Value

As investors increasingly prioritize first-year performance and long-term degradation behavior, module reliability has become a defining metric for project bankability.

During his presentation, Fully Vertically Integrated Value Chain: GCL’s Commitment to Reliable Solar Energy, Malachi emphasized that controlling reliability requires control over the entire value chain. GCL’s strategy is built on vertical integration that begins at the silicon atom level and extends through:

- Metallurgical silicon production

- FBR granular polysilicon manufacturing

- Ingot growth

- Wafer slicing

- Cell processing

- Module assembly

This integrated approach enables tighter control over material purity, wafer defect density, and cell passivation quality—key variables that influence long-term module stability.

FBR Granular Silicon: Purity and Carbon Efficiency

A central element of GCL’s reliability framework is the use of a fluidized bed reactor (FBR) for granular polysilicon. Compared with conventional Siemens-process polysilicon, FBR technology offers both quality and sustainability advantages.

GCL maintains impurity levels below 0.5 parts per billion in its FBR material, supporting consistent downstream cell performance. In parallel, third-party verification reports a carbon footprint of 14.4 kg CO₂-equivalent per kilogram of polysilicon, significantly reducing embedded emissions within the module lifecycle.

End-to-End Traceability

Beyond materials control, GCL has implemented a batch-level traceability system covering silicon, wafers, cells, and modules. Production data and reliability test results are recorded across manufacturing stages.

The system has been audited by TÜV Rheinland and is integrated at the product level through QR-coded identification on the SIRO module series. Data integrity is ensured through blockchain-based records, which reinforce transparency for customers and investors.

Managing Early-Life and Long-Term Degradation

To address early-life performance loss, GCL presented laboratory data on UV-induced degradation (UVID). Under UVID-60 accelerated testing conditions:

- The GCL modules recorded approximately 1.2% degradation.

Comparable products in the market have shown degradation levels approaching 5%

In addition, bifacial dual-glass modules were tested under IEC 61215 mechanical reliability standards, including:

- Damp heat

- Thermal cycling

- UV exposure

Extended internal testing beyond IEC requirements was also conducted. Reported degradation remained below the 5% IEC threshold.

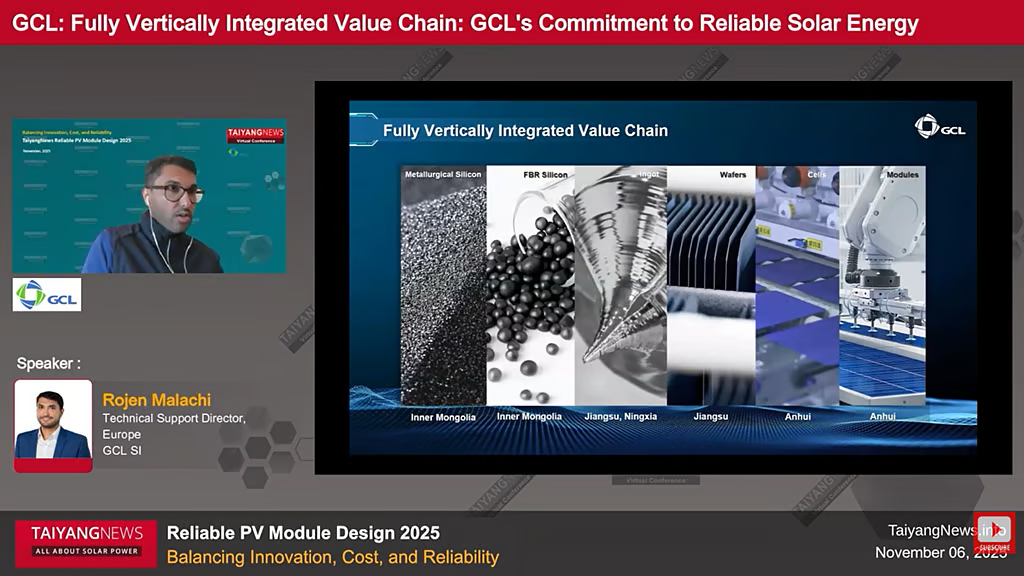

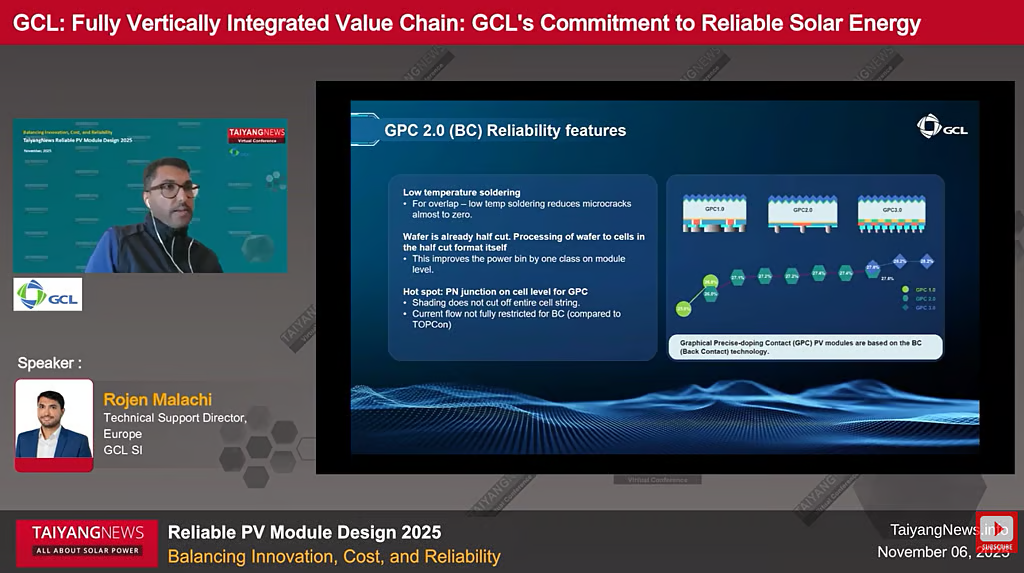

Back-Contact, TOPCon, and Perovskite Technology Updates

Malachi also discussed reliability considerations associated with GCL’s back-contact (GPC) module architecture. In the presentation, he explained that low-temperature soldering, linear busbar layouts, and optimized current-flow design are implemented to enhance shade tolerance, reduce the risk of hotspot formation, and limit the propagation of micro-cracks. These features were identified as particularly relevant for rooftop installations and other partially shaded environments.

GCL also presented reliability-related developments within its TOPCon platform, including the use of 3-cut and 4-cut cell structures and a 26-busbar configuration. These design choices are intended to lower operating current and reduce mechanical stress within the module.

In the area of perovskite technology, the company confirmed that its 2 m² single-junction perovskite module has obtained third-party certification. GW-scale production of perovskite–silicon tandem modules has recently commenced in China, with global rollout expected from mid-2026.

Building Long-Term Confidence in Solar Performance

As module architectures evolve and efficiency increases, reliability requirements become more demanding. GCL’s vertically integrated manufacturing model, advanced materials control, extended reliability validation, and next-generation platform development collectively reinforce its commitment to stable, predictable, and sustainable solar energy solutions worldwide.