In a recent video interview with TaiyangNews, Philipp Matter, President of Europe & Americas and Vice President of the Global Sales & Marketing Center at GCL SI, highlighted the company's comprehensive approach to building an ultra-low-carbon value chain in solar energy. He emphasized GCL’s commitment to innovation, sustainability, and transparency, positioning the company as a frontrunner in the transition toward greener solar solutions.

During the interview, Matter outlined GCL’s strategic initiatives to reduce the carbon footprint across the entire solar supply chain. These include advanced FBR silicon products, the company's latest innovations in modules—such as back contact (BC) and perovskite technologies—and digital traceability tools that enhance transparency and ESG compliance.

The Advancing FBR Silicon

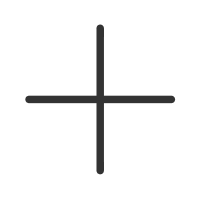

A key aspect of GCL’s sustainability efforts lies in its polysilicon production. GCL is, in a way, the only player utilizing fluidized bed reactor (FBR) technology to produce granular polysilicon—a low-cost, energy-efficient alternative to conventional Siemens process. FBR technology features more continuous process steps, unlike the batch-based Siemens method. It operates at a nominal temperature of 700°C, significantly lower than the 1,100°C required by its counterpart. Recently, GCL achieved a new French ADEME certification for the carbon footprint of its FBR silicon product at 14.441 kg CO2e/kg, setting a new benchmark for raw material sustainability in the solar industry. This method consumes over 70% less energy and results in a carbon footprint up to 42% lower, significantly reducing the environmental impact of silicon production. With an annual capacity of 480,000 tons, GCL’s FBR technology is well-positioned to meet rising demand for sustainable silicon globally.

The Commercial Practice on Back Contact Module

Since May 2024, GCL has invested in capital and R&D to develop back contact module technology, culminating in the release of its GPC (Graphical Precise-Doping Contact) modules by the end of last year. The GPC modules integrate TOPCon technology with a BC architecture. At Intersolar Europe 2025, GCL debuted its latest GPC module in Europe for the first time, achieving an efficiency of 24.8% and a power output of 480W. The module is already on sale in China and is scheduled for European release by September 2025, according to Matter.

During a previous product launch event, GCL announced that their 660W GPC module reaches a conversion efficiency of 27.5%. This marks a significant technological breakthrough, and its commercial availability marks a key milestone in GCL’s strategy to expand its product portfolio for diverse market segments.

The Perovskite Showcase

In the order of visitor interest, perovskites earn the first mention. GCL exhibited a single-junction large-format perovskite PV module and a tandem module using crystalline silicon and perovskite. While the former is a perovskite on glass, the latter is a module tandem, i.e., perovskite-on-glass integrated on the top of a crystalline module. This is called the 4-terminal (4T) approach, where 2 different modules are fused together to work in tandem. For clarity, a major chunk of PV manufacturers and research centers are working on a tandem at the cell level, also referred to as 2-terminal (2T).

As to the specs, the single-junction perovskite module, measuring 2×1m, achieves a steady-state efficiency of up to 19.04%. On the other hand, the perovskite/silicon tandem version is labeled with an efficiency of up to 26.36% for a 1.71 m² surface area.

According to Matter, GCL has already signed its first commercial supply and testing agreement for perovskite modules with a European partner during Intersolar. The company currently operates 100 MW of perovskite production capacity, while the building that houses this capacity can hold up to 2 GW. In its next stage of expansion, GCL aims to reach 500 MW, which is expected to be online by Q4 2025. “This is the future,” Matter said, highlighting GCL’s determination to be among the first to industrialize perovskite solar modules at scale.

SiRo - GCL’s Exclusive Carbon Data Platform

Another key highlight in the interview was GCL’s digital carbon footprint tracking platform SiRo, which integrates modules with a QR code linked to a blockchain platform. This system offers transparent traceability of the module’s origin and full visibility into its carbon footprint. “You know exactly how much carbon has been used and where the modules come from,” Matter explained. As carbon accounting and ESG compliance gain prominence, especially in Europe, such embedded traceability tools might turn out to be interesting in procurement and project financing decisions.

*This article is based on content from TaiyangNews and has been modified and adapted by GCL System Integration(GCL SI).